Continually investing in people, equipment and advanced processes

Dependable. Reliable. Committed to Customer Satisfaction.

We are situated on approximately 14 acres in Oxford, Alabama, conveniently located just off Interstate 20 between Atlanta and Birmingham. Our facility encompasses 125,000+ square feet of climate- controlled manufacturing and warehouse space, and our Quality Management System is AS9100D and ISO 9001:2015 certified. We maintain an exceptionally clean and organized work environment in order to drive the best results for our customers. As our customer, you will always be our top priority.

We possess decades of experience sourcing castings, and providing in-house CNC precision machining services. We utilize advanced manufacturing processes, continually invest in new equipment, and employ an expert staff of engineers, machinists and customer service reps to deliver precision finished parts, kits and assemblies.

A partial list of our equipment is listed below.

Horizontal Machining Centers

Haas EC-500 40 Taper 500mm Twin Pallet System

Hyundai Kia HS400 40 Taper 400mm Twin Pallet System (2 each)

Hyundai Kia HS4000i 40 Taper 400mm Twin Pallet System

Hyundai Wia HS6300 630mm Twin Pallet System

Hyundai Kia HS5000 500mm Twin Pallet System

Okuma MA-500H II 50 Taper 500mm Twin Pallet System (2 each)

Okuma MA-500H II 50 Taper 500mm with 6 Station APC

Okuma MA600HB II 50 Taper 600mm Twin Pallet System

Okuma MB4000H 400mm Twin Pallet System

Okuma MA600HB II 50 Taper 600mm with 6 Station APC

Okuma MB-10000 1000mm Twin Pallet System

Vertical Machining Centers

Daewoo DMV4020 with 5th axis

Haas DT-1 Drill/Tap Center 20x16x15.5”, 30 Taper

Haas VF-2 with 4th axis (2 each)

Haas VF-2SS (2 each)

Haas VF-3

Haas VF3-YT50 50 Taper with 4th axis

Haas VF5/40XT

Hyundai Wia F400VM

Hyundai Wia F500VM with 4th axis

Okuma M460 with 4th axis (3 each)

Okuma M560V with 5 Axis Trunion

Okuma M560V with 4th axis Midaco Pallet System (2 each)

Okuma M560V with Midaco Pallet System (2 each)

Lathes

Haas ST-25Y with Live Tooling

Hyundai Wia L300MC with live tooling – 20" turning capacity

Hyundai Wia L400C – 24” turning capacity

Hyundai Wia LF2600M/2SP with live tooling - 12" turning capacity

Hyundai Wia LV500L Vertical Lathe – 22” turning capacity

Hyundai Wia LV500RM Vertical Lathe with Live Tooling – 22” turning capacity

Hyundai Wia LV800RM Vertical Lathe with live tooling – 30” turning capacity

Kia 21LMS, sub spindle with live tooling - bar feeder 2.625 bar capacity

Momentum MVL-16M

Okuma LB3000EXII with live tooling – 16” turning capacity (5 each)

Okuma LB4000EXII 1000mm with live tooling – 19” turning capacity (3 each)

Okuma & Howa Model 2SP-15H Twin Spindle – 8” turning capacity

Okuma & Howa HL-JR – 8” turning capacity

Tsugami M08SY II Turning Center with Live Tooling and Sub-Spindle

Robotic Lathe Cells

Okuma Genos L300 Dual Live Tool Lathe with Fanuc Load N Go Robotic System -13” turning capacity

Okuma LB3000EXII Live Tool Lathes with Fanuc Robotic Handling System with integrated Tigo SF CMM – 16” turning capacity

Okuma LB3000EXII Live Tool Lathes with Fanuc Robotic Handling System – 16” turning capacity

Okuma Genos L3000-E Live Tool Lathes with Fanuc Robotic Handling System – 13” turning Capacity

Tsugami M08SY II Turning Center with Fanuc Load N Go Robotic System

Complete Quality Control & Engineering Lab

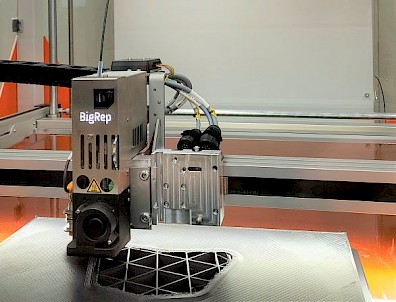

BigRep ONE.4 3-D Printer System

Brown & Sharpe Global Classic CMM with PC-DMIS Inspection Software (3 each)

Brown & Sharpe Manual CMM

Brown & Sharpe PC-DMIS Offline CMM Workstation (2 each)

Hexagon Tigo Shop Floor CMM (5 each)

Cloudray 50W Fiber Laser Marking Machine Engraver (2 each)

Elbo Controlli Tool Pre-setter

Keyence IM Series Digital Optical Comparator

LMT Cobalt Dominator 20PF – Laser Marking System (2 each)

Masterview MV14P Optical Comparator

Newage Model NB3010 Brinell Hardness Tester

Universal Testing 315Q Tensile Test Machine

Zoller Centurion Tool Pre-setter

Other

Birmingham Manual Mill with DRO

Chevalier FSG-618M Surface Grinder

Cosen C-320NC Horizontal Band Saw with Conveyor System

Cress Electric Heat Treat Oven

Enco Vertical Band Saw

JET Horizontal Band Saw

JET Mill Drill

Monarch Manual Engine Lathe

Nishijimax 110 CNC Cold Saw with Automatic Bar Loader (2 each)

Nishijimax 230 CNC Cold Saw with Automatic Bar Loader

Rego-Fix Tabletop powRgrip Tool-setting Unit

Sharp LC185V Manual Mill with DRO

Techniks 00500-HD Shrink Fit Machine

Victor 1440GS Manual Lathe

Victor 1660S Manual Lathe

Victor JF-4V S Manual Mill with DRO